Tomato Crates

Co-Partner Design Experience

CHALLENGE

Collaborate with “We the People Farms”, a nonprofit supporting formerly incarcerated individuals, to design a transport system for tomatoes. The crates needed to be durable, protective during transit, easy to carry, and stackable for storage and distribution.

Insights

Through direct conversations with the organization, we learned that traditional bins were damaging produce and difficult to move. The key needs were cushioning, stackability, and ease of handling, built from cost-effective, sustainable materials.

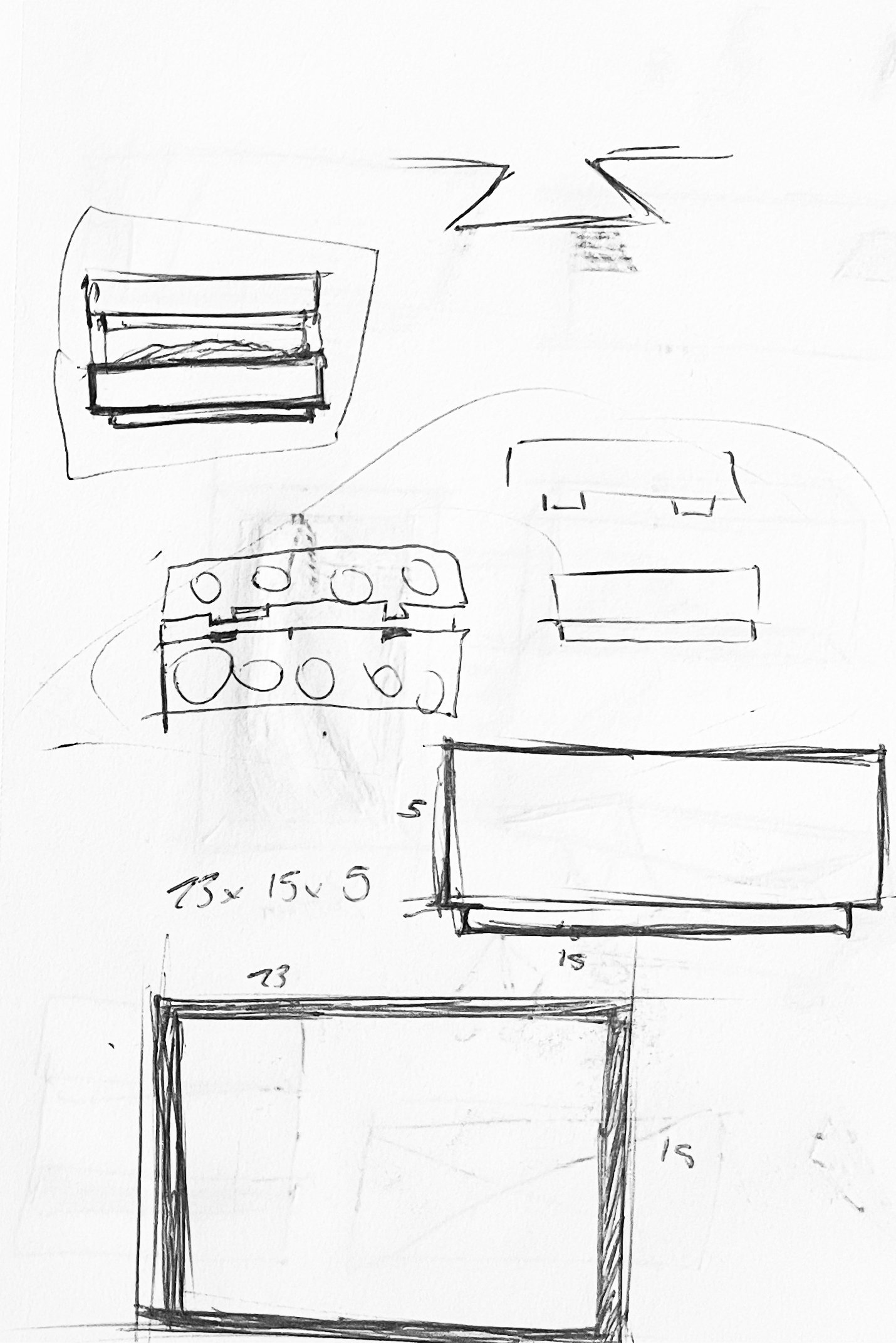

INITIAL THINKING & SKETCHING

Working with a team of three other designers, we quickly sketched ideas that addressed structure and stacking. We evaluated different crate joints and form factors for strength and modularity. After prototyping several concepts, my crate design was selected for full production due to its balance of simplicity, strength, and manufacturability.

PROTOTYPING & PRODUCTION

Once the final design was approved, we milled our own lumber and began fabrication. As a team, we built 60 full crates in just a few weeks; over 200 combined hours in the shop. For many teammates, this was their first time working with wood, so I helped guide construction and solve fabrication challenges.

Final Product & Features

A durable, easy-to-carry crate system built for real-world farming logistics

Modular design allows crates to nest securely when stacked

Protective build prevents damage to tomatoes during transit

Ergonomic Handles allow for efficient two-handed lift

Rapid fabrication is possible with these easy-to-build crates