Automotive Luxe Trim

Seating & Trim Development Project

Challenge

Automotive seat covers must balance luxury aesthetics with strict trim constraints and manufacturing limitations. The challenge was to design and develop a seat cover that reflected a strong design theme while also being practical to produce, addressing issues like wrinkling, gaps, and material bridging.

Insight/Research

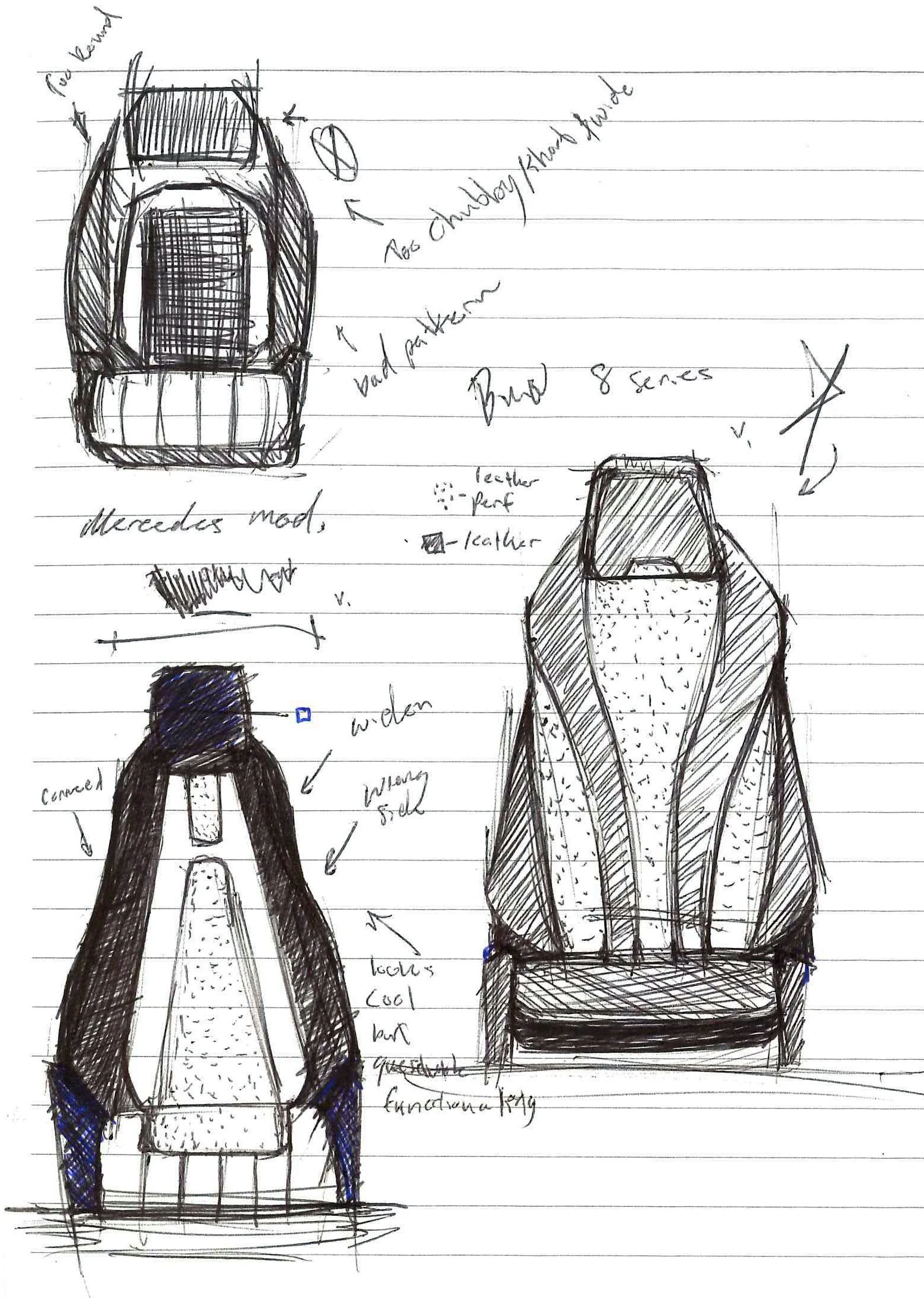

Market research into luxury interiors revealed two key references:

BMW 8 Series Gran Coupé →

fluid form, dynamic trim

Mercedes-AMG GT Coupé →

modern, sculpted form

The insight was to merge these directions into a design that communicates elegance without sacrificing comfort or manufacturability. Material research showed limited availability, requiring creative flexibility in color and texture combinations.

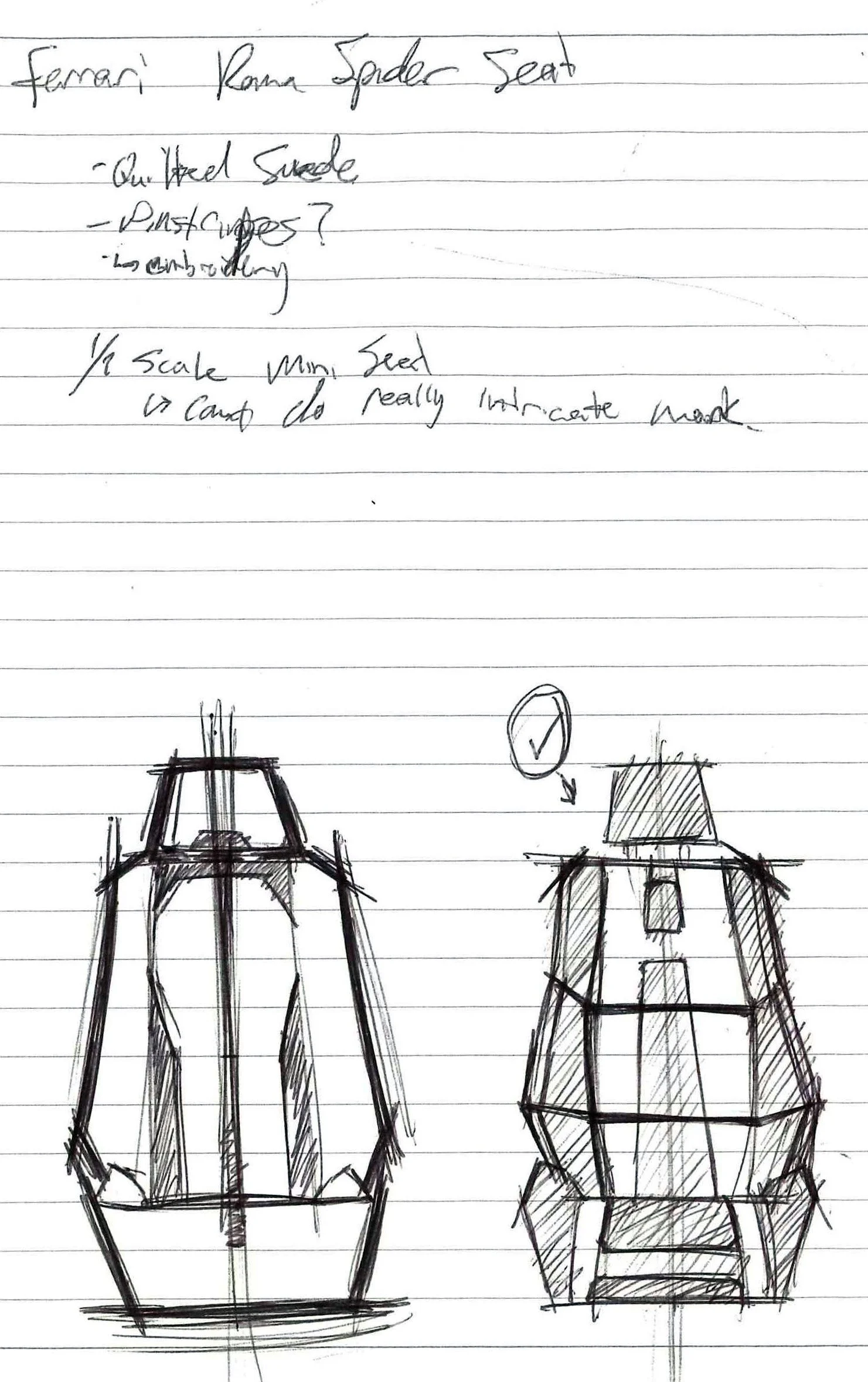

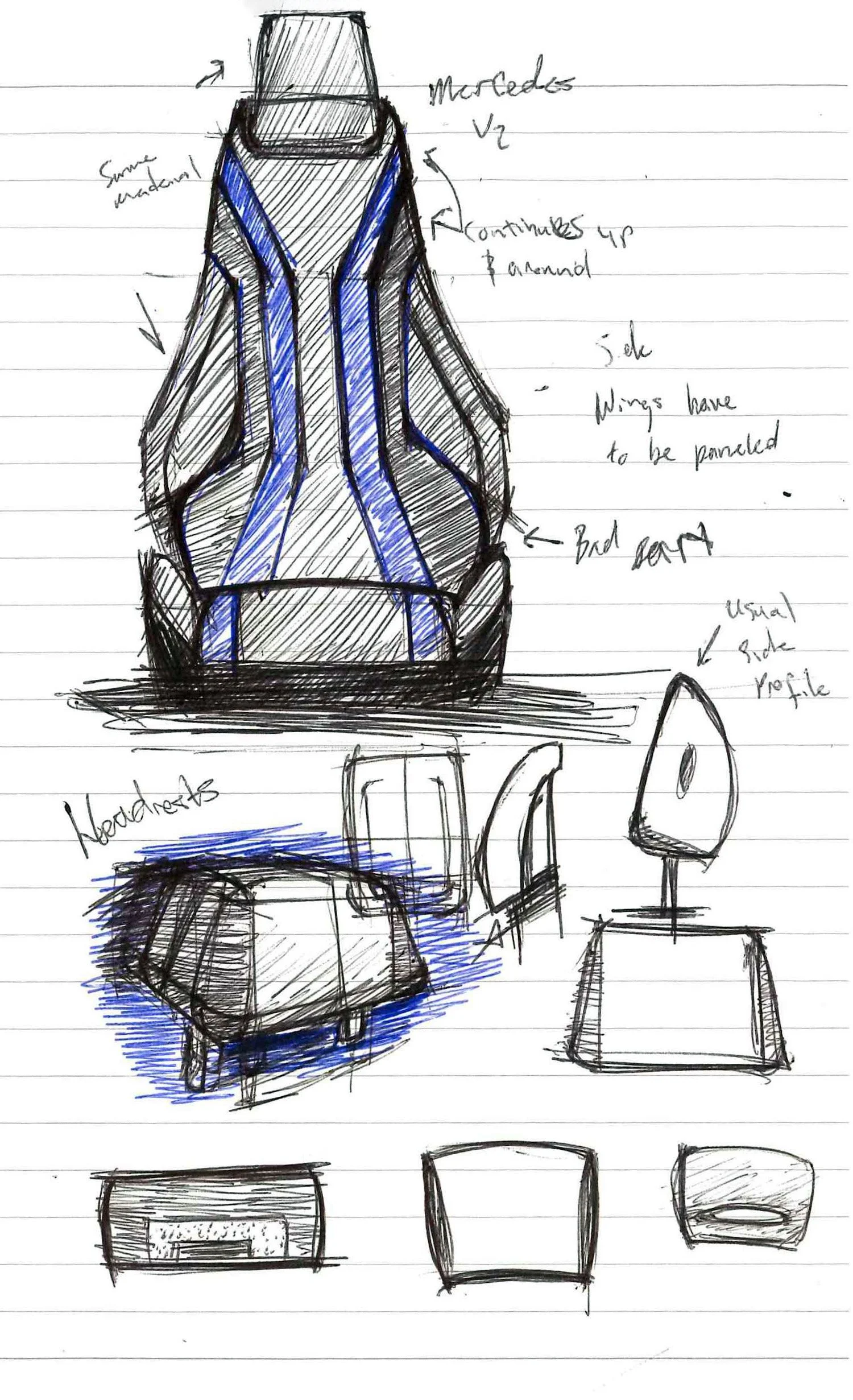

Early Thinking

I explored natural forms to guide the design language and landed on the tulip as a thematic inspiration. Its flowing silhouette became the foundation for the seat’s form. While testing ideas, I initially considered multiple bold color combinations but quickly saw that a more restrained approach would better communicate a luxury feel.

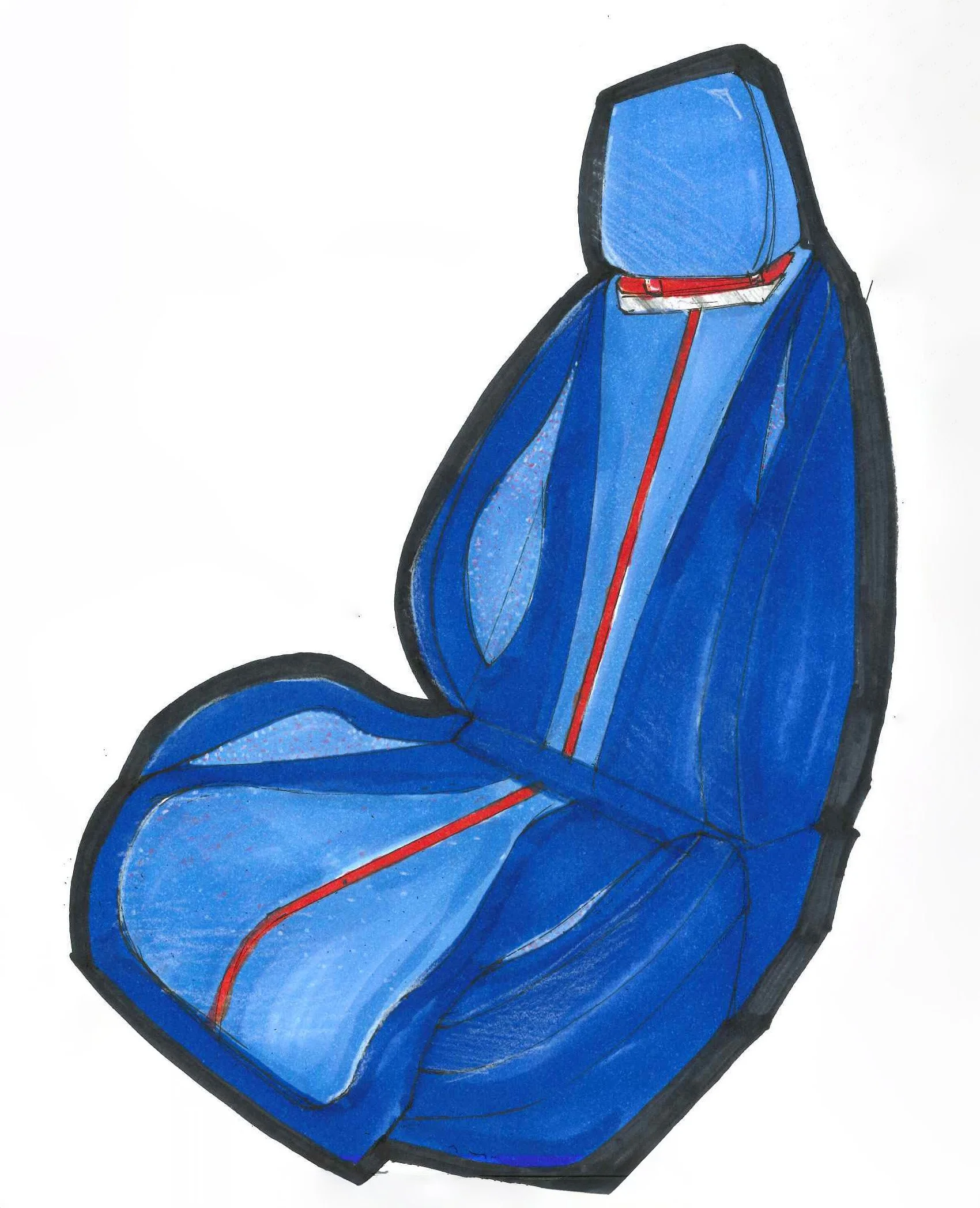

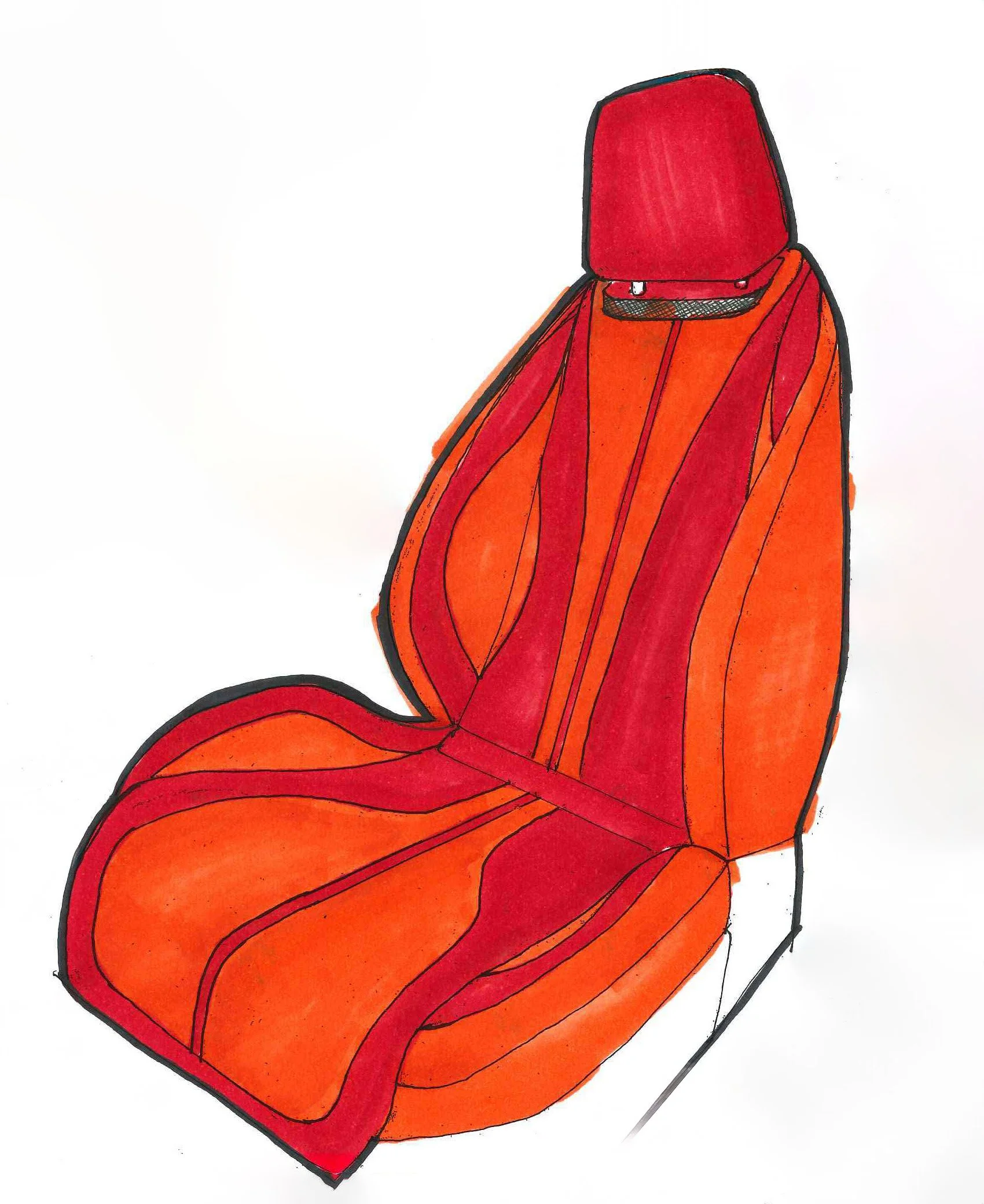

Color Exploration

A series of 12+ sketches focused solely on experimenting with color palettes for the seat. These ranged from bold, high-contrast combinations to more subtle tonal variations. Through iteration, I learned that leaning on material differences with restrained color use created the most refined and effective direction.

Final draft emphasized a clean, luxury aesthetic with minimal color contrast

Prototyping & DEvelopment

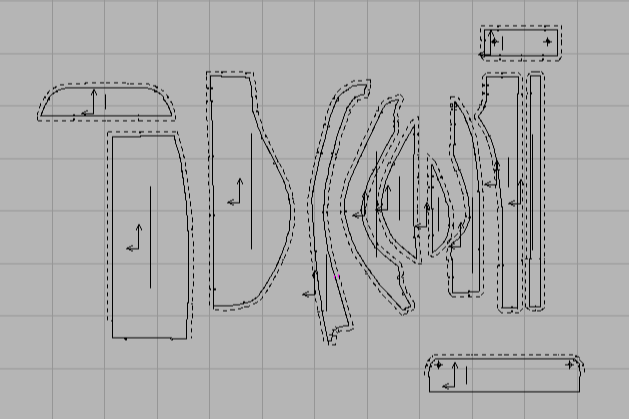

Patterning by Hand → drafted on custom foam, cut via mylar templates. This phase highlighted the compounding effect of even small inaccuracies.

CAD Patterning → digitized templates for precision. Transitioning from physical to digital revealed how minor adjustments could ripple through the design.

Hands-On Sewing → early builds exposed challenges like excess material, misaligned notches, and seat bagginess, all of which informed refinements.

Iteration

Refinements were guided by continuous testing and mentor feedback. Sourcing premium leather from Eagle Ottawa added real-world constraints around sizing, color, and perforation. Adjustments to headrest design focused on maintaining cohesion with the seat while ensuring comfort and manufacturability.

Key lessons included:

Always allow safety margins when cutting materials.

Plan for supply chain delays when working with premium materials.

Small design decisions have an outsized impact in physical production.

Final Outcome

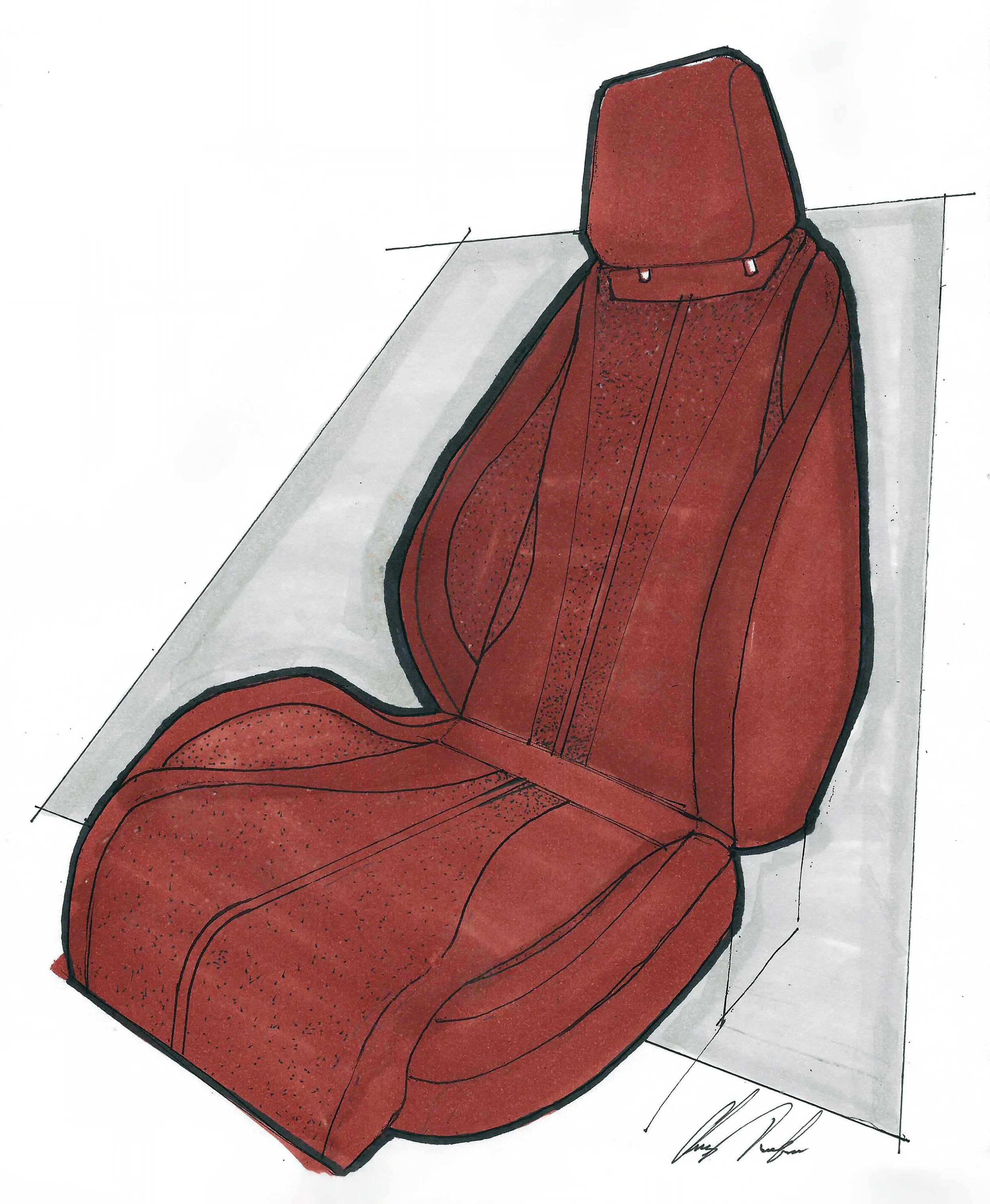

A luxury tulip-inspired seat cover that balances aesthetic ambition with production reality.

Tulip-inspired form created a flowing, elegant seat silhouette

Luxury aesthetic through material contrast rather than heavy color-blocking

Digitally refined patterns ensured precision and repeatability in manufacturing